How to deal with motor desync

Motor desync can be caused by various factors. Please follow the steps below to troubleshoot:

🔋 1. KV Rating Does Not Match the LiPo Battery

If the motor KV doesn’t match the LiPo cell count, it can lead to vibrations, desync, or overheating.

- For 4S batteries, we recommend using 2300–2700KV motors.

- For 6S batteries, we recommend 1700–1900KV motors.

⚙️ 2. PWM Frequency Too High

Excessively high PWM frequency can cause motor stuttering or overheating.

The ideal PWM frequency varies by frame, motor, propeller, and other components.

Higher PWM frequency does not always mean smoother flight.

If the default value doesn’t work well for your build:

- Start from the lowest value (usually 16kHz),

- Gradually increase it,

- After each test flight, check motor temperature immediately to prevent overheating.

Sometimes higher PWM frequency feels smoother, but also runs motors hotter. If the motors are warm but not hot, it’s generally acceptable.

🛠️ 3. ESC Firmware Settings Adjustment

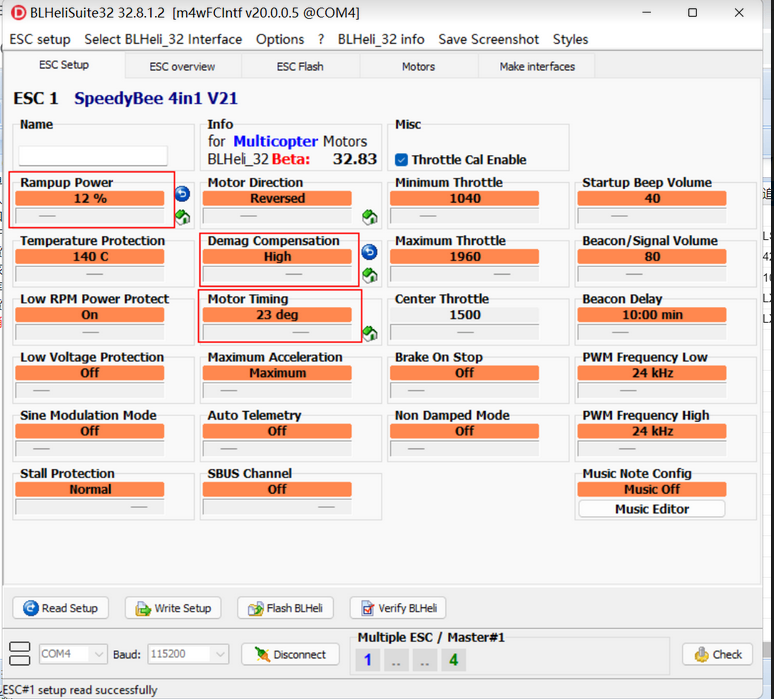

For BLHeli_32 ESCs:

- Startup Power: 12–15%

- Motor Timing: 22–30 degrees

- Demag Compensation: High

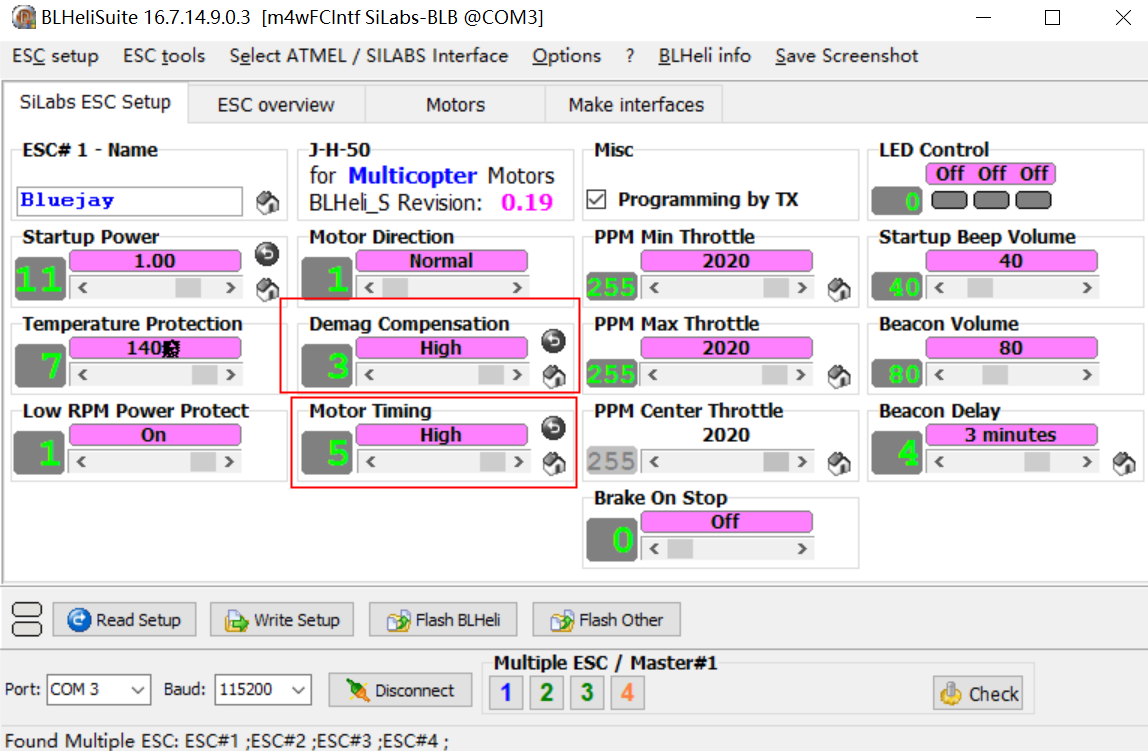

For BLHeli_S ESCs with BLS firmware:

- Motor Timing: High

- Demag Compensation: High

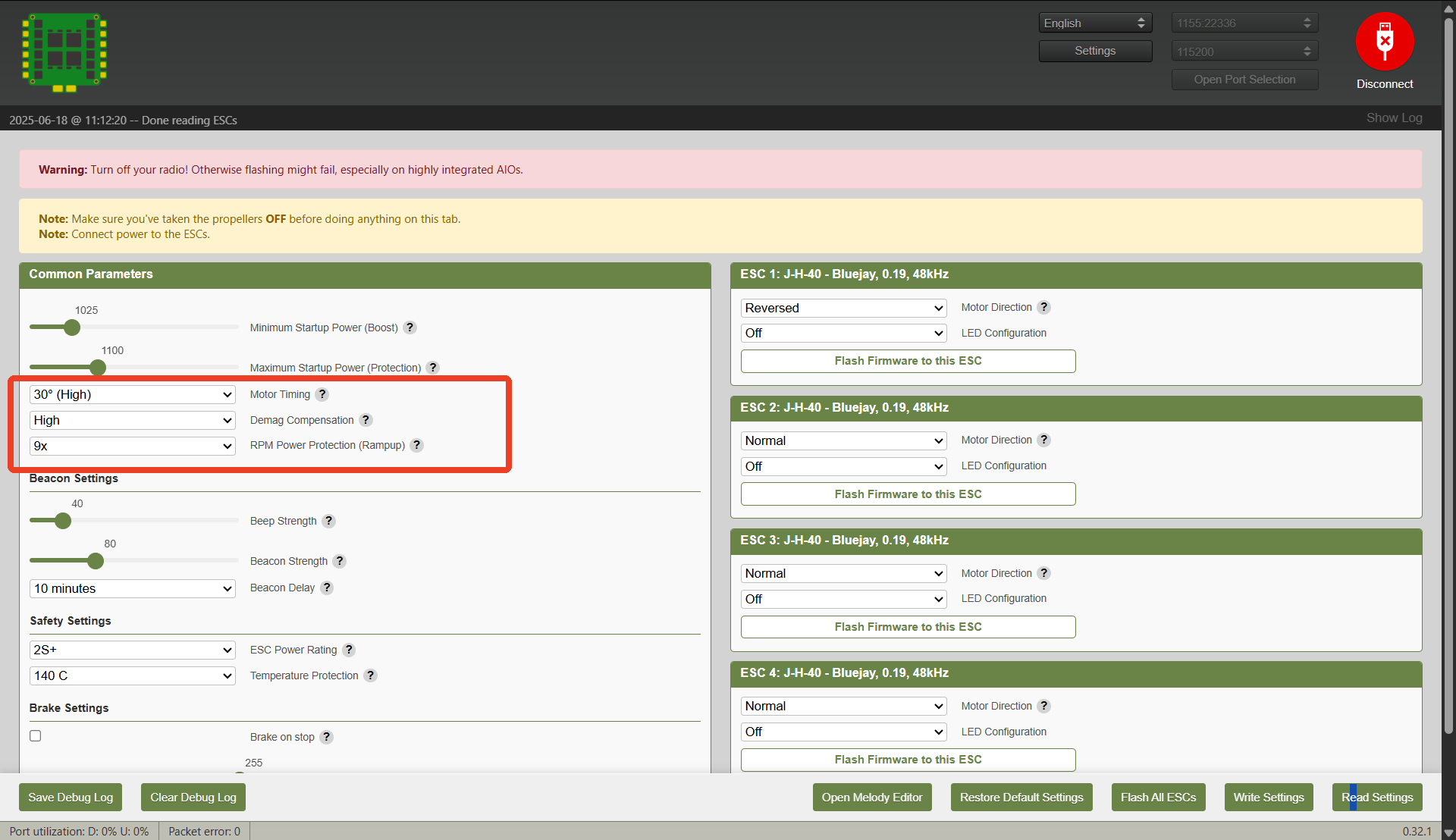

For BLS ESCs using Bluejay firmware:

If your BLS ESCs don’t have Bluejay firmware yet, it’s recommended to flash Bluejay.

- After flashing, set: Motor Timing: High Demag

- Compensation: High

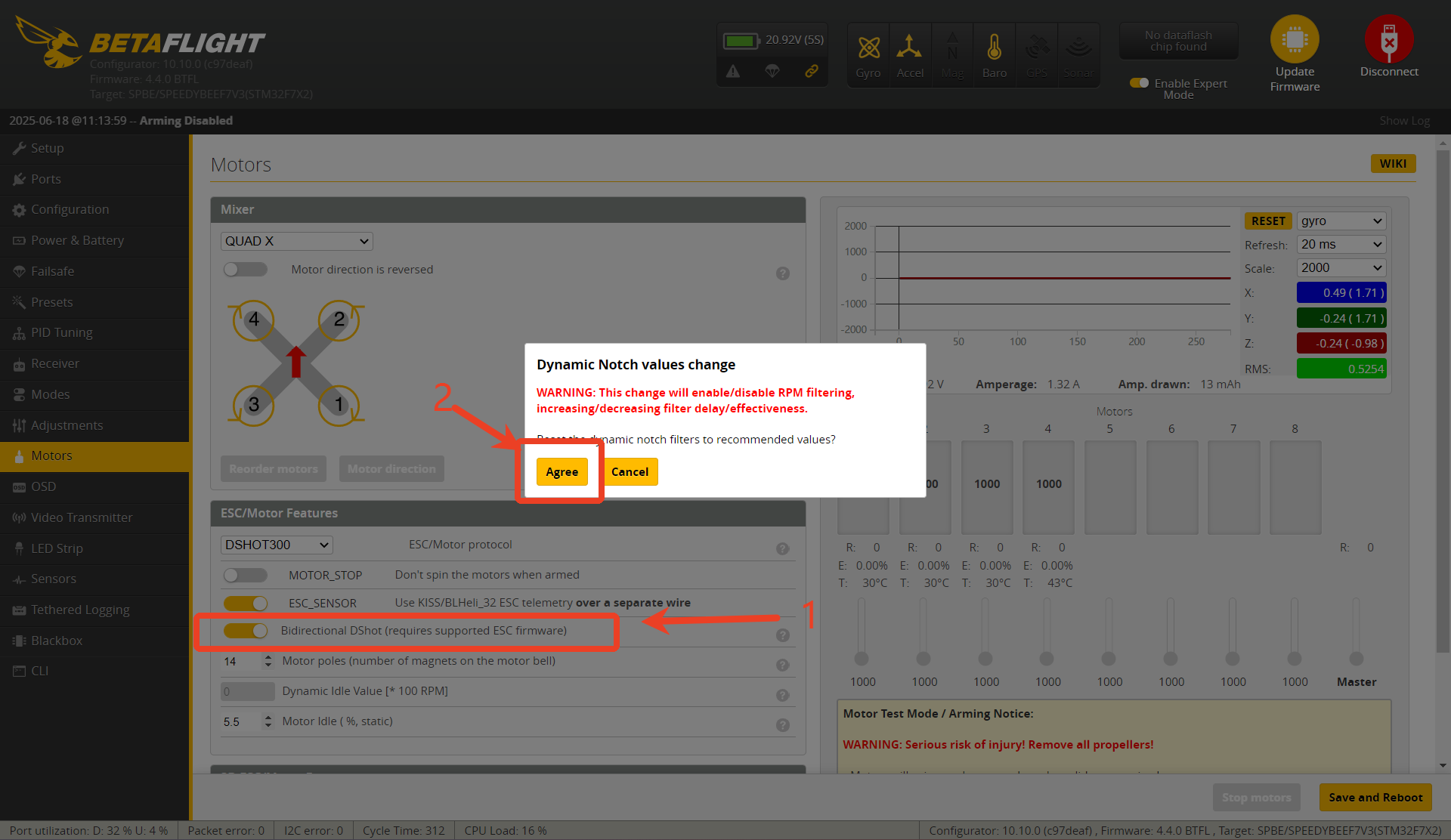

If you’re using 32-bit ESCs or 8-bit BLS ESCs with Bluejay firmware,

you can enable Bidirectional DShot and use RPM Filtering.

🧩 4. Check Flight Stack Installation

Inspect the physical setup for potential mechanical issues:

- Ensure stack nuts are not overtightened (which can compress/damage soft mounts).

- Avoid routing wires over the flight controller.

- Make sure no wires are pulling on the FC — leave some slack.

- Ensure battery wires are not pressing against the flight controller.

- Check that frame screws are properly secured.

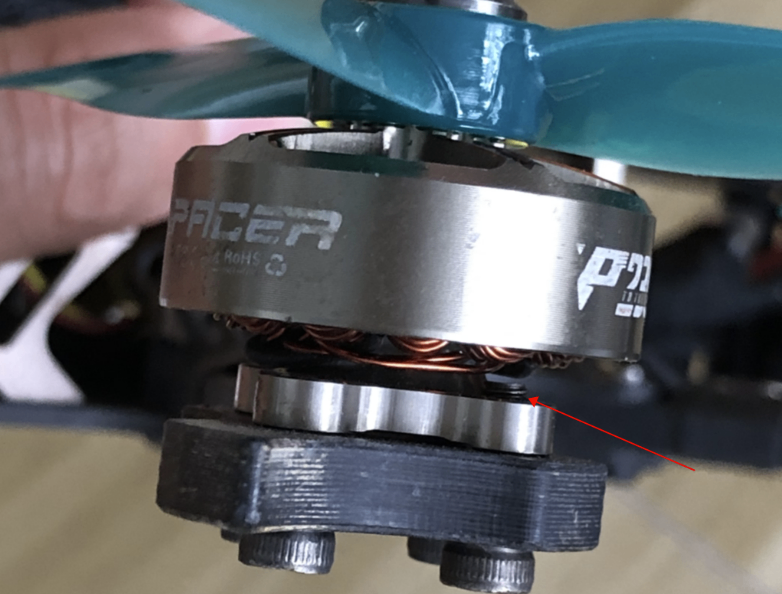

🔍 5. Inspect Motor Screws

Finally, inspect all four motors for mounting screws that may be touching the internal windings.

If any screw contacts the winding, the motor may behave erratically or even burn out.

(See illustration below if available.)